Top stories

Construction & EngineeringSmart city infrastructure gets a boost with FNB's new toll solution

16 Apr 2025

Marketing & MediaBiz Promoted Features: Keep your business headlines in the spotlight for 7 days

Bizcommunity.com 16 Apr 2025

More news

Marketing & Media

IAB SA: 6 key trends impacting influencer marketing

Casey Mantle,Dashni Vilakazi,Jolene Roelofse & Sanesh Maharaj 17 Apr 2025

Marketing & Media

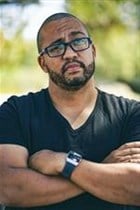

Adelaide Tshabalala | Why community managers are the digital Queen Bees

Adelaide Tshabalala 17 Apr 2025

Finance

Godongwana defends VAT increase, saying ‘severe consequences’ await if hike is suspended

Estelle Ellis, Suné Payne, Lerato Mutsila and Ethan van Diemen 3 hours

Construction & Engineering

"Cape Town’s water recycling project should not be privatised"

Finance

PwC shuts operations in 9 African countries

Bipasha Dey, Kanjyik Ghosh and Harshita Meenaktshi 16 Apr 2025

Construction & Engineering

Cape Town inner city development opportunity lies in regeneration